Electric power can be transferred by overhead transfer system or with the help of the underground cables. Cables are the group of wires and are designed according to the need or demand. Power cables are one of the cables which are used for the purpose of power transferring and for distribution purpose. There are 2 types of power cables – one is the electrical power cable and the other one is the flexible power cable. Electrical power cables are meant for the installation for the permanent purpose in buildings or in houses. Flexible power cables are in portable devices like laptops or mobiles etc. Power cable wire manufacturer is the one who design and produce the power cables.

These power cables are produced as per the customer requirement, voltage it should carry, temperature and as per the purpose. For example for extraction purposes, the strength provided to cable is double in that case. In case of wind plant, the requirement is more flexible- electrical cables and so on. Which size you need for your conductor depends upon the ability to carry the short circuit. There are many important aspects in the construction of the power cable. Power cable is consists of these parts:

- Conductor

- Insulation

- LAY for multi cables

- Bedding

- Armouring

- Outer sheath

- Conductor: conductors are the pathway to carry the power in power cable. Conductors are made up of different material as according to the requirement of particular industry. For example: in cable sector, conductors are made up of copper. There are different classes of conductors like: class 1, class 2, class 5, class 6 etc.

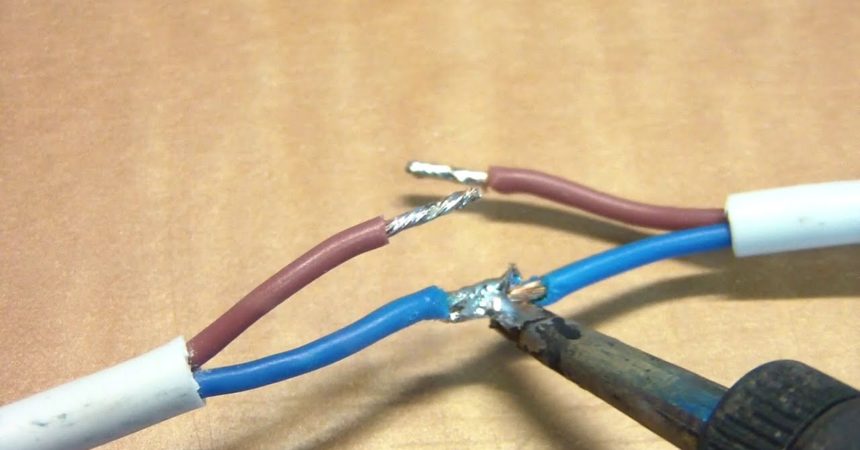

- Insulation: the material of the insulation is basically based on the temperature where it is going to operate. Insulation is provided by rubber, PVC etc.

- Multicore cables: cores are represented by the colours and different colours are used in various cores.

- Bedding: Bedding is also known as inner sheath which is an inner cover of the cable. These are mainly used under multi core cables. These act as a bond between the conductors and multi core cables. This inner cover is made up of PVC.

- Armouring: these are galvanized wires or galvanized steel which are placed on the inner sheath of the cable. Armouring is the process of setting earthing shield to the conductors and it is also used for the purpose of earthing of the cable to maintain the safety. In case of failure of insulation in the conductor, the current will get a path to flow in the cables if earthing is done carefully. Armouring aims at providing the extra protection or safety to the cable.

- Outer sheath: this is the outer cover of the cable which is generally made up of PVC i.e. poly vinyl chloride or of rubber. Outer covers is the protection given to the cables. Wire suppliers aim at providing the earth safety to the cables to avoid any kind of short circuit. Power cables are defined mainly by the voltage grades etc.